Appearance

Thermal conductivity of three phase structure

For details about the effective thermal conductivity calculation, please see here.

Overview

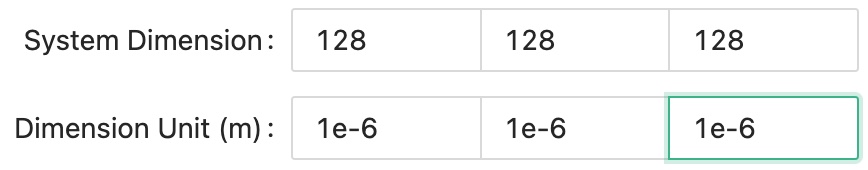

First, we will setup a cubic simulation with 128 microns along each dimension, that is 128 simulation grids times 1 micrometer for each grid.

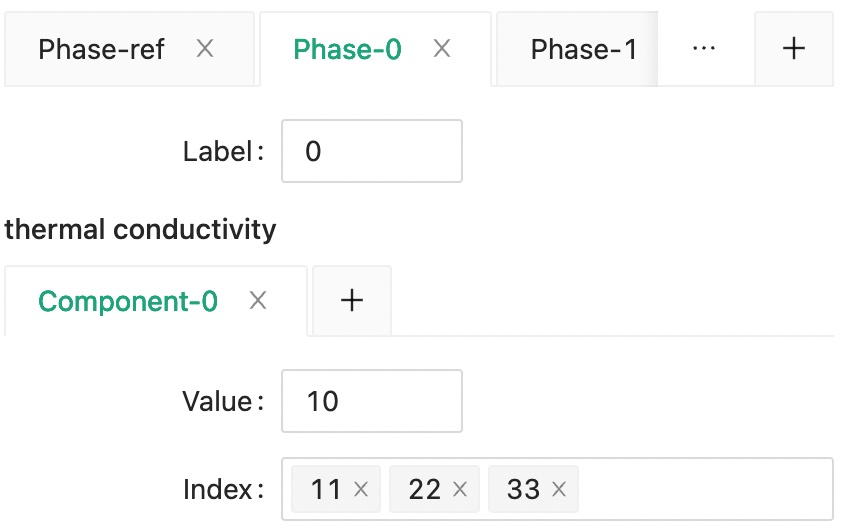

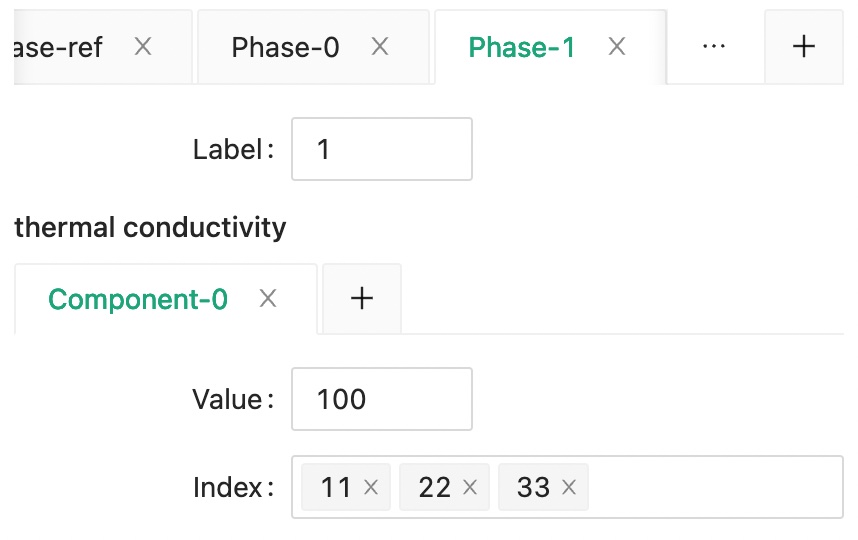

Next, we will add three phases into the system, one for the matrix phase, another for the slab with higher conductivity, and the other for the embedded particle with lower conductivity.

Lastly, we will setup a structure with slab and random ellipsoid for the composite material.

Step 1: Fill Input

Follow the introduction to the input part in the user manual and make sure you fill all of the blank boxes in the following four sections.

Dimension

Output

Choose vti for the output format, since we may want to visualize with Paraview.

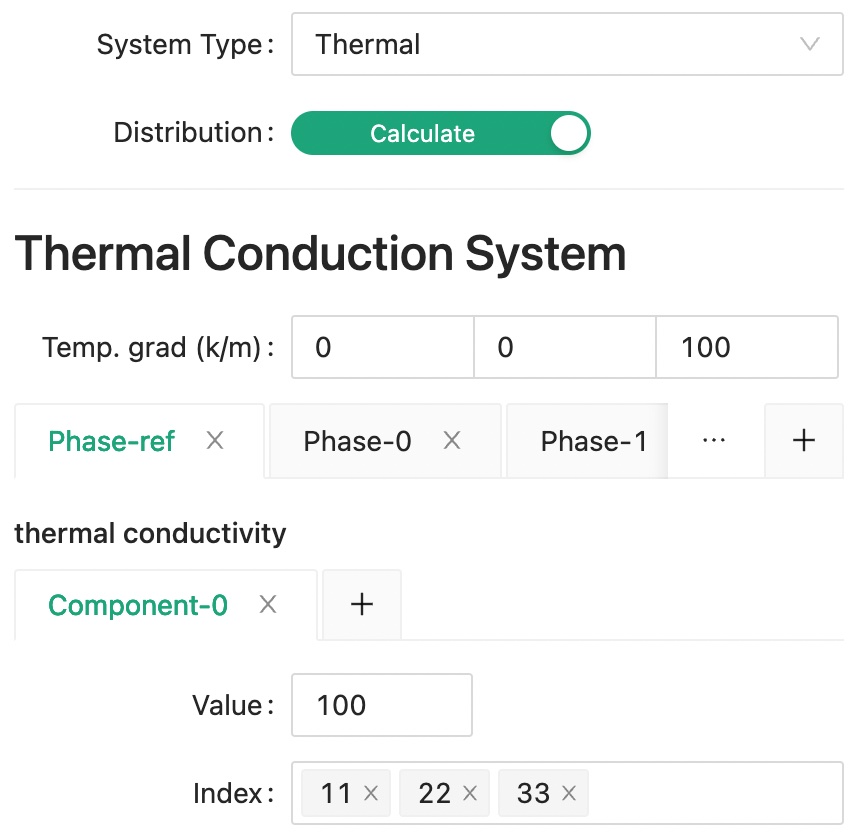

System

Choose "Thermal" system for the System Type. Besides from the effective properties of thermal conductivity, we also want to calculate a field distribution under external applied thermal gradient, so we need to turn on the Distribution switch and set an Tenp. grad (k/m) value, the temperature gradient in kelvin per meter.

Next, set the reference thermal conductivity value to be used in our solver.

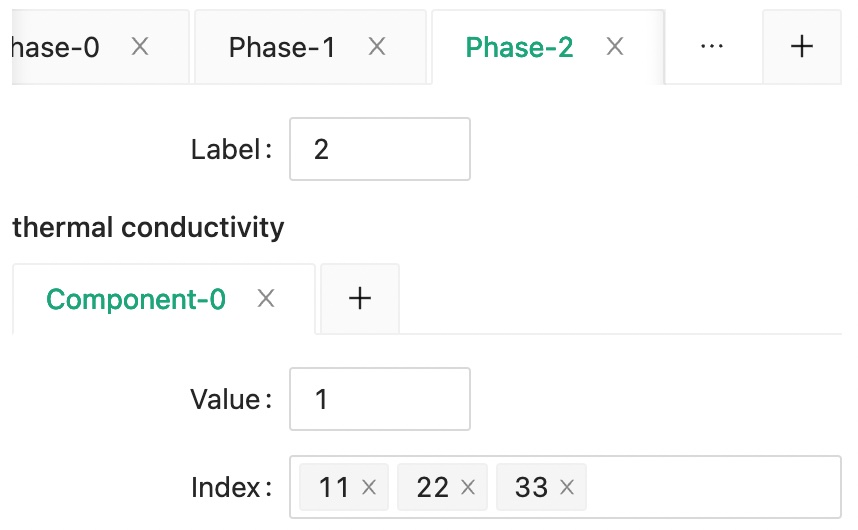

Then, set the thermal conductivity for the three phases.

Structure

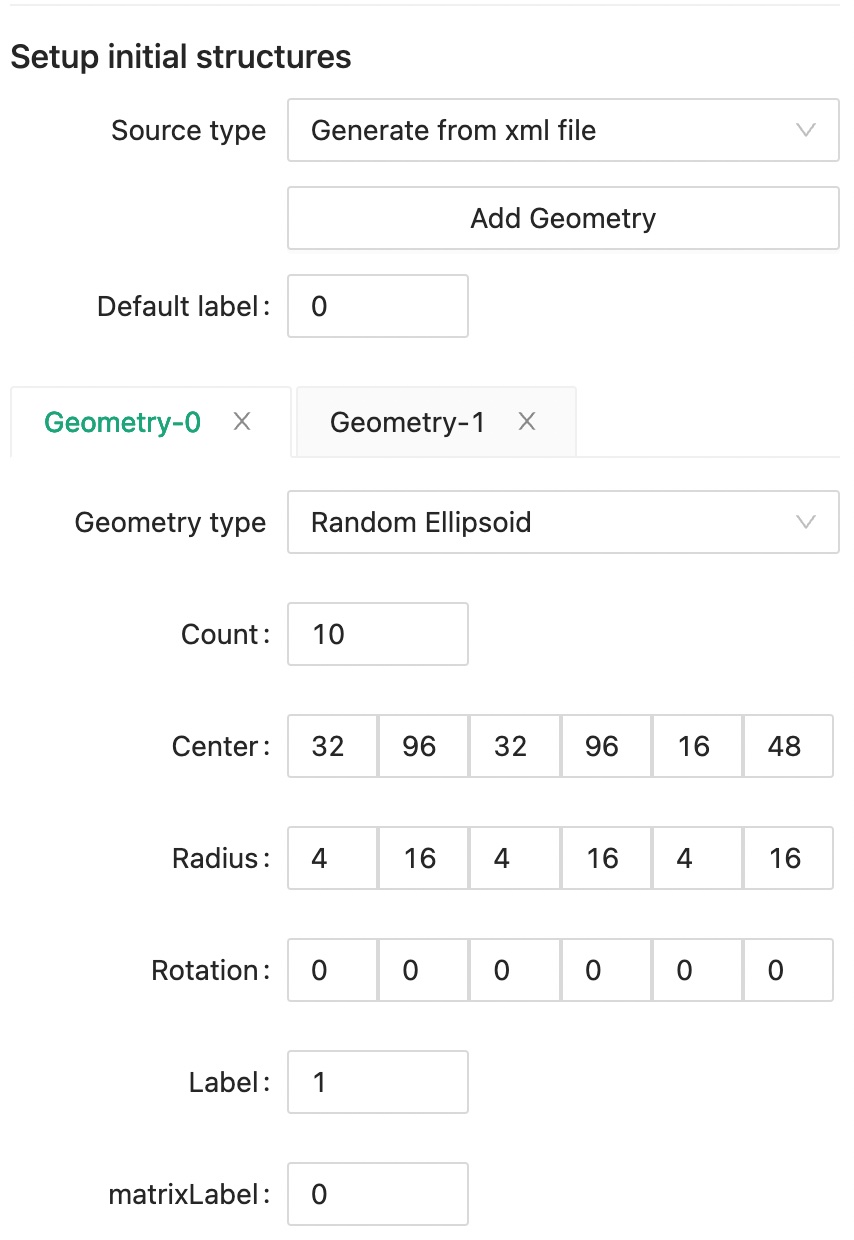

Since we want to generate the structure within the effective properties simulation program, we should choose "Generate from xml file" for the Source type.

Click Add Geometry button to create a new geometry tab, and set label 0 as the Default label.

We want to create 10 randomly generated ellipsoids whose centers are located in the lower half of the 128 cube, and leave the upper half for the slab.

The ellipsoid radius is random value between 4 to 16 grid points, and there is no rotation added to the ellipsoid.

We will assign phase label 1 to this newly defined geometry and set its matrix label to be phase 0.

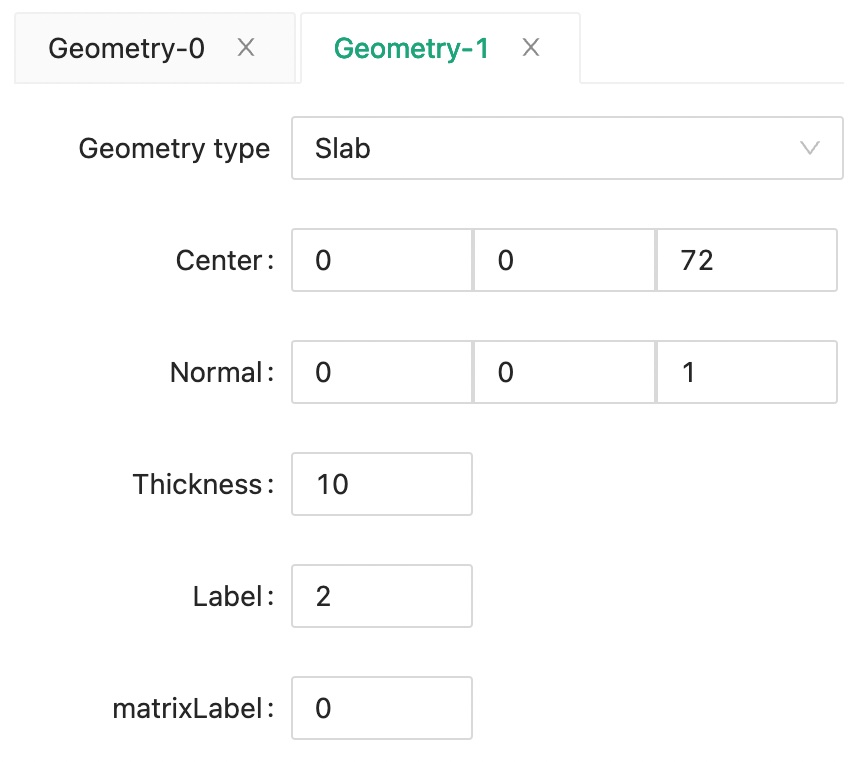

To set the slab structure, we click the Add Geometry again and choose Slab for Geometry type

Step 1.5: Or Import Input

If you don't want to enter all of the values manually, you may import the following input file directly into the software.

Save the following content into a local file, then click the File -> Import in the menu to read your saved file.

<input>

<dimension>

<nx>128</nx>

<ny>128</ny>

<nz>128</nz>

<dx>1e-6</dx>

<dy>1e-6</dy>

<dz>1e-6</dz>

</dimension>

<output>

<format>vti</format>

</output>

<system>

<type>thermal</type>

<distribution>1</distribution>

<external>

<temperatureGradient>

<x>0</x>

<y>0</y>

<z>100</z>

</temperatureGradient>

</external>

<solver>

<ref>

<tensor>

<name>thermal_conductivity</name>

<rank>2</rank>

<pointGroup>custom</pointGroup>

<component>

<value>100</value>

<index>11</index>

<index>22</index>

<index>33</index>

</component>

</tensor>

</ref>

</solver>

<material>

<phase>

<label>0</label>

<tensor>

<name>thermal_conductivity</name>

<rank>2</rank>

<pointGroup>custom</pointGroup>

<component>

<value>10</value>

<index>11</index>

<index>22</index>

<index>33</index>

</component>

</tensor>

</phase>

<phase>

<label>1</label>

<tensor>

<name>thermal_conductivity</name>

<rank>2</rank>

<pointGroup>custom</pointGroup>

<component>

<value>100</value>

<index>11</index>

<index>22</index>

<index>33</index>

</component>

</tensor>

</phase>

<phase>

<label>2</label>

<tensor>

<name>thermal_conductivity</name>

<rank>2</rank>

<pointGroup>custom</pointGroup>

<component>

<value>1</value>

<index>11</index>

<index>22</index>

<index>33</index>

</component>

</tensor>

</phase>

</material>

</system>

<structure>

<matrixLabel>0</matrixLabel>

<sourceType>xml</sourceType>

<geometry>

<type>ellipsoid_random</type>

<count>10</count>

<centerXMin>32</centerXMin>

<centerXMax>96</centerXMax>

<centerYMin>32</centerYMin>

<centerYMax>96</centerYMax>

<centerZMin>16</centerZMin>

<centerZMax>48</centerZMax>

<radiusXMin>4</radiusXMin>

<radiusXMax>16</radiusXMax>

<radiusYMin>4</radiusYMin>

<radiusYMax>16</radiusYMax>

<radiusZMin>4</radiusZMin>

<radiusZMax>16</radiusZMax>

<rotationXMin>0</rotationXMin>

<rotationXMax>0</rotationXMax>

<rotationYMin>0</rotationYMin>

<rotationYMax>0</rotationYMax>

<rotationZMin>0</rotationZMin>

<rotationZMax>0</rotationZMax>

<label>1</label>

<matrixLabel>0</matrixLabel>

</geometry>

<geometry>

<type>slab</type>

<centerX>0</centerX>

<centerY>0</centerY>

<centerZ>72</centerZ>

<normalX>0</normalX>

<normalY>0</normalY>

<normalZ>1</normalZ>

<thickness>10</thickness>

<label>2</label>

<matrixLabel>0</matrixLabel>

</geometry>

</structure>

</input>

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

Step 2: Export Input

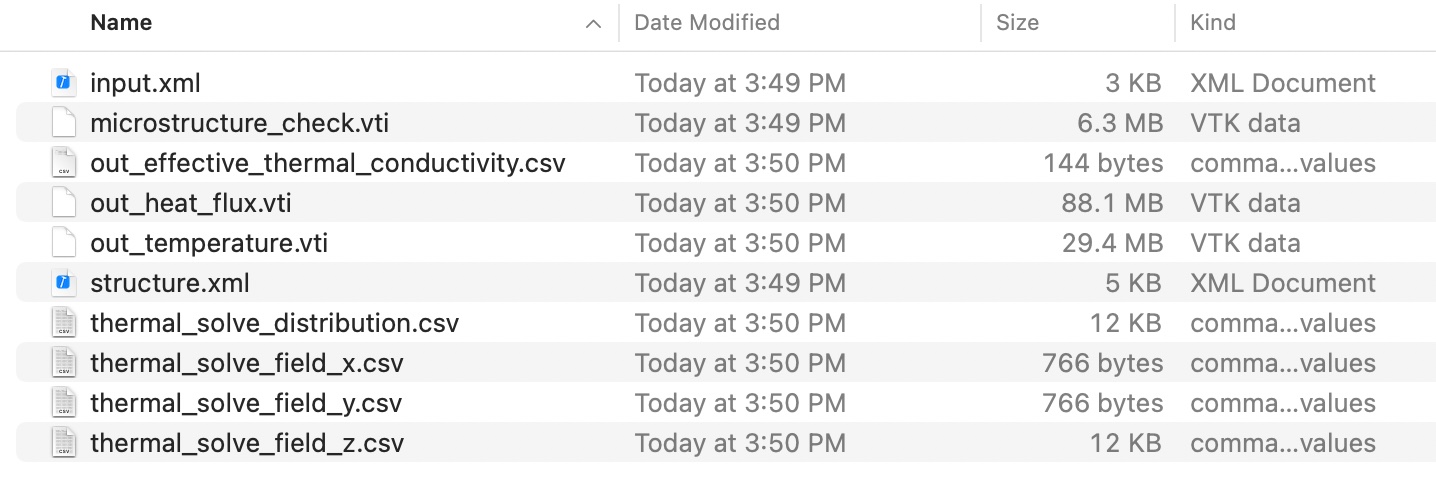

Click the Create Inputs button. Select the folder that you want to run the simulation in, and create a file named input.xml.

This step is simple but very important because the input.xml file is a prerequisite for starting any calculation.

Step 3: Run calculation

Make sure you have finished Step 2, you have to click the Create Input button, because it will both export the input.xml file and set the current working directory to that folder.

Then, you can click the Start simulation button to start the calculation. If you have not click the Create Input button and create the input.xml file, nothing will happen because the program does not know where to look for the input.xml file.

Step 4: Check Output

You will see the following output files in your simulation folder. Meaning for each of the files are explained in the Dielectric System.

Overall, there are two types of output data, vti files for 3D data, and csv files for tabular data.

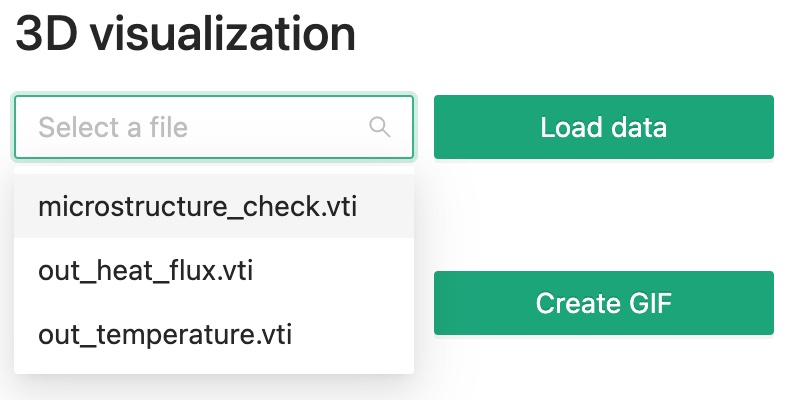

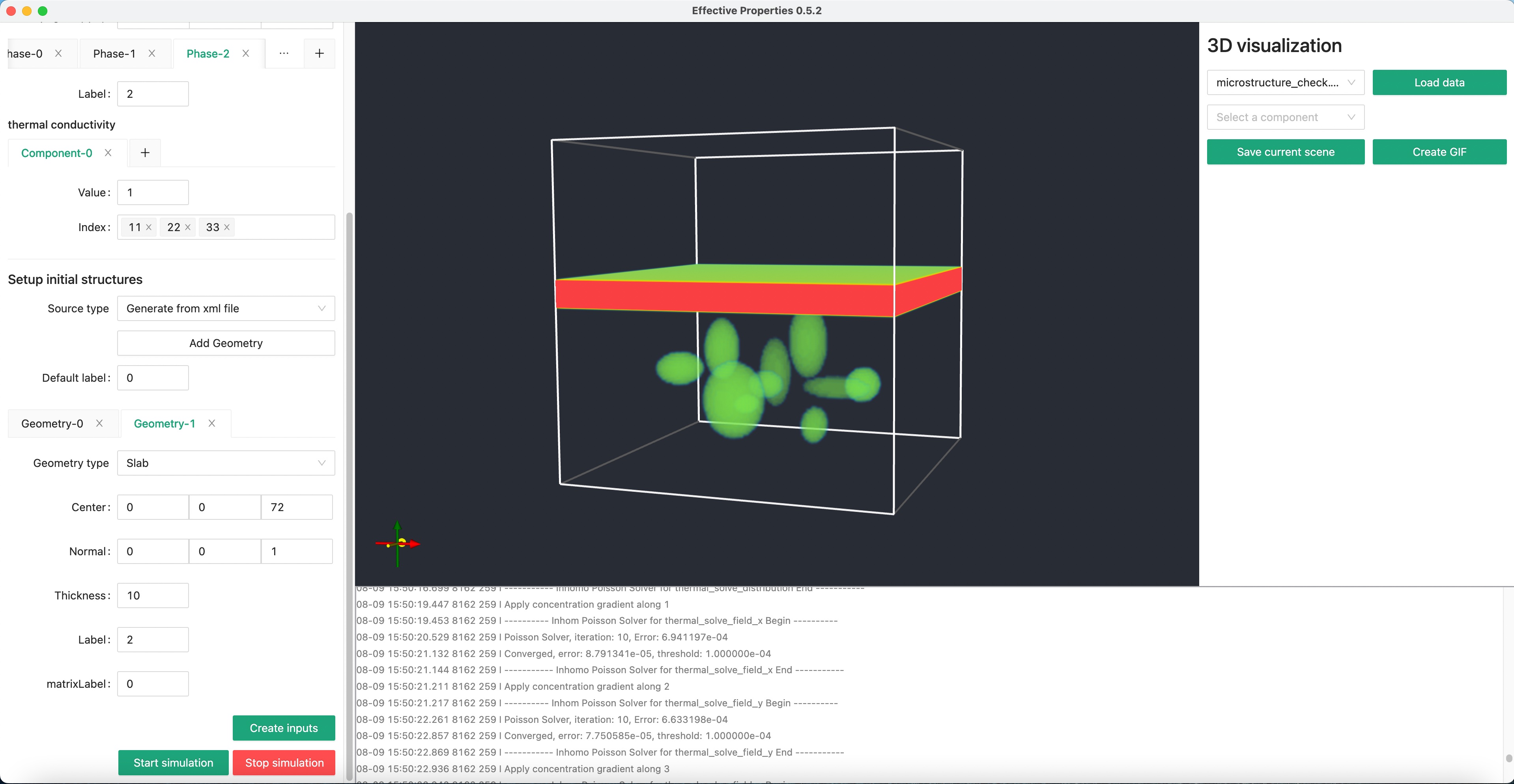

Step 4.1: Check 3D data

Within our software, you can quickly check a 3D vti data file.

Select the file you want to visualize using the dropdown menu, then click Load data button.

Then you will see something like this.

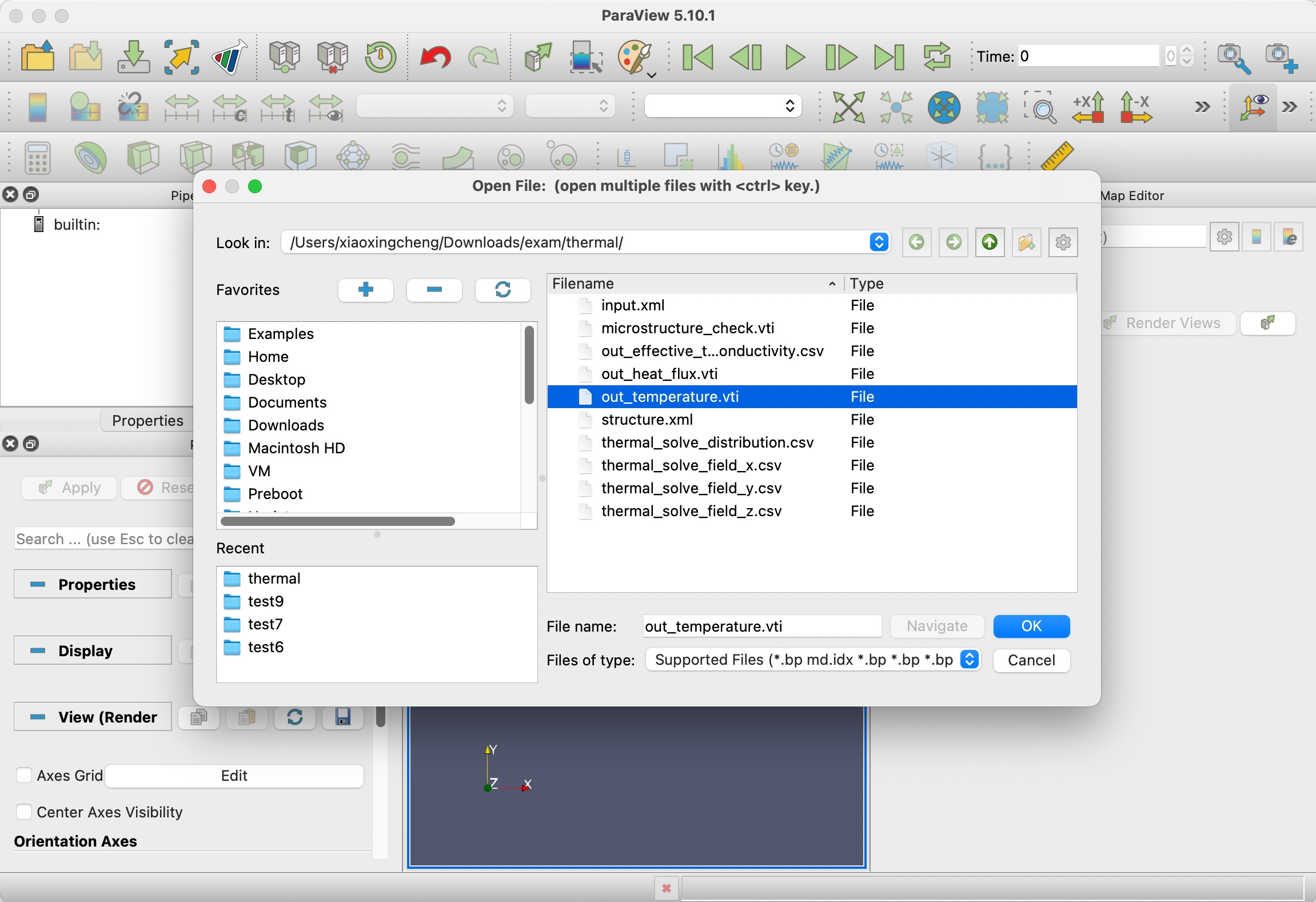

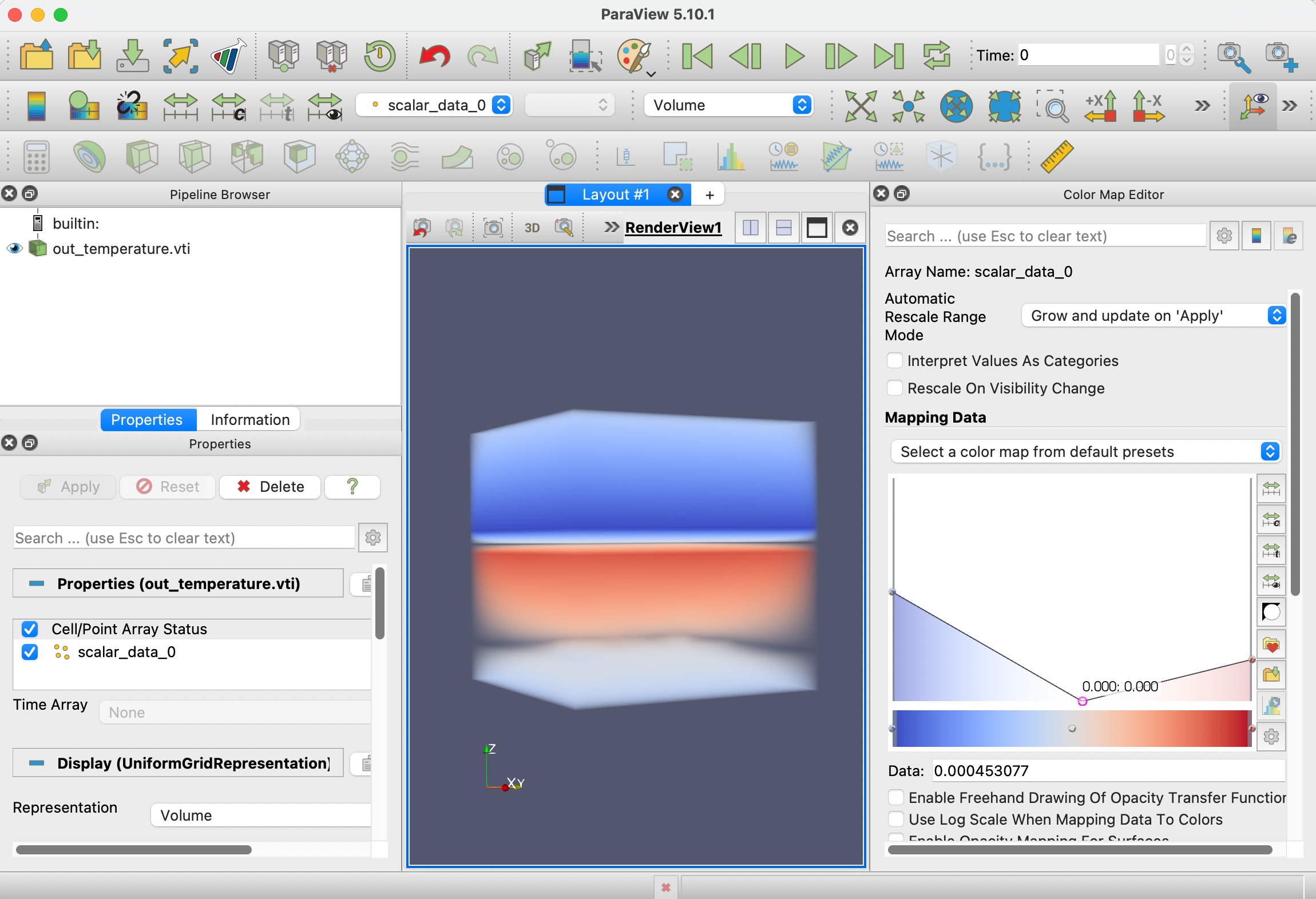

Step 4.2: Paraview

Next, we can try visualizing other files with Paraview. Click the first Open icon in the tool bar.

After the data is loaded, click Apply, then switch to Volume rendering and choose scalar_data_2, which is electric field along z for visualization.

We also need to tune the color lookup table to add some transparency to the data.

Step 4.3: Check tabular data

Though 3D data looks cool, the more important thing probably is still the effective permittivity, out_effective_permittivity.csv.

| Index | 1 | 2 | 3 |

|---|---|---|---|

| 1 | +9.580886e+00 | +1.757357e-03 | -4.381574e-03 |

| 2 | +1.757357e-03 | +9.566548e+00 | +1.616383e-03 |

| 3 | -9.079212e-03 | +3.559258e-03 | +6.093892e+00 |